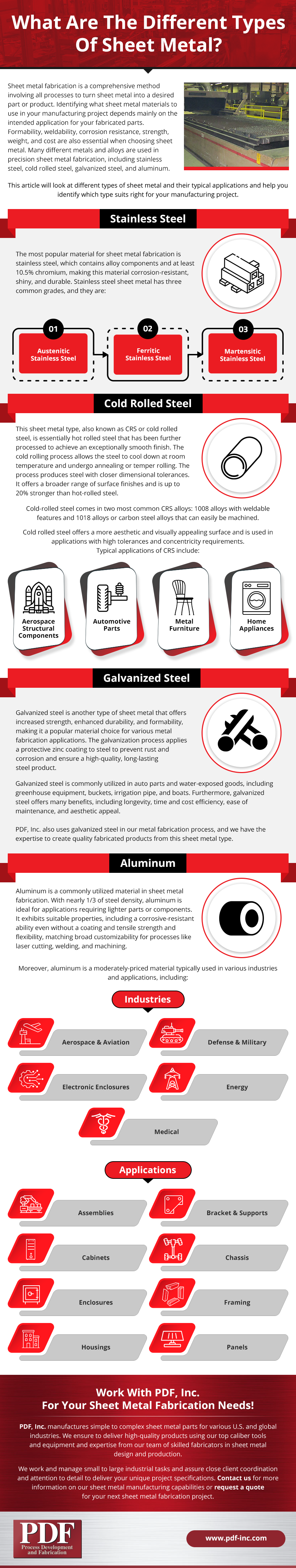

Sheet metal fabrication is a comprehensive method involving all processes to turn sheet metal into a desired part or product. Identifying what sheet metal materials to use in your manufacturing project depends mainly on the intended application for your fabricated parts. Formability, weldability, corrosion resistance, strength, weight, and cost are also essential when choosing sheet metal. Many different metals and alloys are used in precision sheet metal fabrication, including stainless steel, cold rolled steel, galvanized steel, and aluminum.

This article will look at different types of sheet metal and their typical applications and help you identify which type suits right for your manufacturing project.

Stainless Steel

The most popular material for sheet metal fabrication is stainless steel, which contains alloy components and at least 10.5% chromium, making this material corrosion-resistant, shiny, and durable. Stainless steel sheet metal has three common grades, and they are:

- Austenitic stainless steel. This widely used grade is non-magnetic and labeled as 300 series stainless steel. It is known for its formability and resistance to corrosion because of its low carbon components and high levels of nickel and chromium elements.

- Ferritic stainless steel. This metal grade is magnetic, non-heat-treatable, and labeled as 400 series stainless steel. It contains little to no amount of nickel and 11-30% chromium. It is commonly used for non-structural applications that require good corrosion resistance, like decorative or aesthetic applications.

- Martensitic stainless steel. This grade offers both corrosion resistance and heat treatability. Martensitic contains no nickel and features a wide range of hardness and strength levels.

Stainless steel sheet metal is widely used in many industries due to its strength, durability, and high corrosion resistance characteristics. In addition, it can withstand extreme temperatures. Finally, stainless steel is 100% recyclable and can help promote a sustainable and eco-friendly business practice.

Our metal fabrication experts at PDF, Inc. work with various steel types used in sheet metal fabrication, providing you with several options to suit any project and application using steel metal sheets.

Cold Rolled Steel

This sheet metal type, also known as CRS or cold rolled steel, is essentially hot rolled steel that has been further processed to achieve an exceptionally smooth finish. The cold rolling process allows the steel to cool down at room temperature and undergo annealing or temper rolling. The process produces steel with closer dimensional tolerances. It offers a broader range of surface finishes and is up to 20% stronger than hot-rolled steel.

Cold-rolled steel comes in two most common CRS alloys: 1008 alloys with weldable features and 1018 alloys or carbon steel alloys that can easily be machined.

Cold rolled steel offers a more aesthetic and visually appealing surface and is used in applications with high tolerances and concentricity requirements. Typical applications of CRS include:

- Aerospace structural components

- Automotive parts

- Metal furniture

- Home appliances

PDF, Inc. offers sheet rolling services that are quick and economical. With our state-of-the-art CNC sheet metal roller equipment, we can ensure our customers get quality sheet metal and desired finished products.

Galvanized Steel

Galvanized steel is another type of sheet metal that offers increased strength, enhanced durability, and formability, making it a popular material choice for various metal fabrication applications. The galvanization process applies a protective zinc coating to steel to prevent rust and corrosion and ensure a high-quality, long-lasting steel product.

Galvanized steel is commonly utilized in auto parts and water-exposed goods, including greenhouse equipment, buckets, irrigation pipe, and boats. Furthermore, galvanized steel offers many benefits, including longevity, time and cost efficiency, ease of maintenance, and aesthetic appeal.

PDF, Inc. also uses galvanized steel in our metal fabrication process, and we have the expertise to create quality fabricated products from this sheet metal type.

Aluminum

Aluminum is a commonly utilized material in sheet metal fabrication. With nearly 1/3 of steel density, aluminum is ideal for applications requiring lighter parts or components. It exhibits suitable properties, including a corrosive-resistant ability even without a coating and tensile strength and flexibility, matching broad customizability for processes like laser cutting, welding, and machining.

Moreover, aluminum is a moderately-priced material typically used in various industries and applications, including:

Industries:

- Aerospace & Aviation

- Defense & Military

- Electronic Enclosures

- Energy

- Medical

Applications:

- Assemblies

- Bracket & supports

- Cabinets

- Chassis

- Enclosures

- Framing

- Housings

- Panels

If you have a metal fabrication project using aluminum as your sheet metal material, our metal fabrication experts at PDF, Inc. can help you! We offer a variety of manufacturing capabilities, including forming, cutting, and welding aluminum sheet metal.

Work With PDF, Inc. For Your Sheet Metal Fabrication Needs!

PDF, Inc. manufactures simple to complex sheet metal parts for various U.S. and global industries. We ensure to deliver high-quality products using our top caliber tools and equipment and expertise from our team of skilled fabricators in sheet metal design and production.

We work and manage small to large industrial tasks and assure close client coordination and attention to detail to deliver your unique project specifications. Contact us for more information on our sheet metal manufacturing capabilities or request a quote for your next sheet metal fabrication project.