PDF, Inc. will design, construct and install your custom conveyor system. We have designed and built many automated conveyor systems, including panels and control systems. We are well versed in many types of conveyors, including:

A 316 Stainless steel and plastic butter bottle conveyor is used to maintain distance between the bottles. While dropping a large distance in height, it continues to maintain a maximum length in the overall conveyor.

This fully pneumatic station holds eight vertical Aro drills, one horizontal drill, one saw and eight hold-down clamps. Each drill is adjustable in ½” increments. Once the part is rolled into place against the stop, all clamps are activated, the drills engage, drill, and disengage. The saw cuts the end off at the predetermined length, the clamps and stop are released, and the part is rolled out, all working within a five-second time frame.

This pneumatic drilling station holds seventeen ARO drills, all working at the same time. Each drill is removable and / or adjustable as needed. The station itself is mobile and locks back into position after each move.

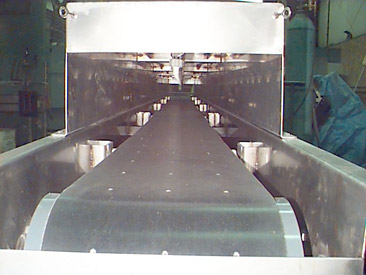

This is a wash / dry conveyor 42 feet long and made from 316 stainless steel. It is designed with several different stations inside, including a neutralizer, washing, rinsing, top dry and side dry. The interval is controlled before items enter the conveyor with a PLC. The wet tanks use high-pressure adjustable nozzles, and the water can be recycled through an additional tank with chemical added as necessary. The top and side air knives are also adjustable.

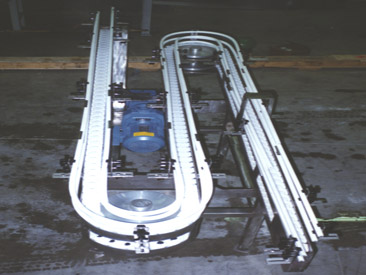

This near fully-emerged stainless steel conveyor has guided interior sloped sides with 4″ flights on the Intralox belt. The tank has a stainless steel frame and inner shell with a painted carbon steel outer shell. The outer shell is fastened with screws to protect the insulation. The drive is maintained outside the water, but when it becomes necessary to remove the entire conveyor for maintenance reasons, this can be completed in about 3 minutes with a come-along or chain hoist.

With conveyors on both ends, this stainless steel pass-through station supplies directed spray in a 360° angle around the part. It has a painted carbon steel base with adjustable feet. Quick connects were used for the water supply and drain.

This stainless steel conveyor uses spray nozzles, directed from the top or sides only, down the entire length of the conveyor. The top has lift-off doors for easy access to all of the spray nozzles. Quick connects were used for water supply and drain.

(click for larger image)