Custom metal fabrication involves the creation of metal products designed and produced to meet specific requirements. This can include anything from large industrial equipment to small components used in consumer products. Moreover, nearly every industry relies on metal fabrication to create products that are unique and tailored to their particular needs.

Choosing the right partner can mean distinguishing between a successful project and one that falls short of your expectations. However, selecting the right partner for your project can be challenging with many fabrication companies available.

This article will explore the key factors to consider when choosing a metal fabrication partner.

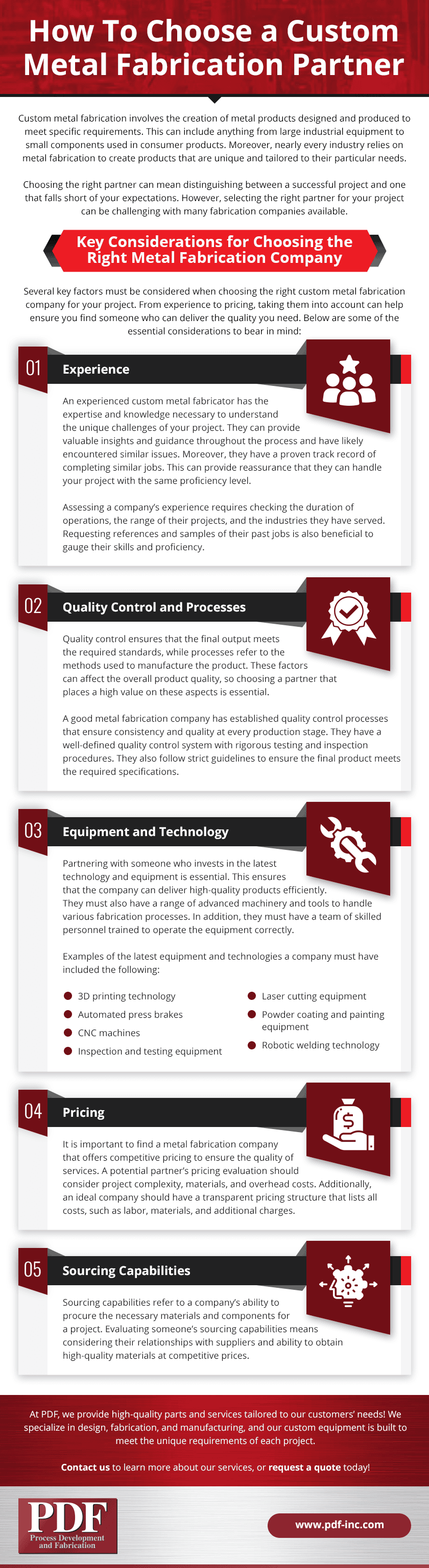

Key Considerations for Choosing the Right Metal Fabrication Company

Several key factors must be considered when choosing the right custom metal fabrication company for your project. From experience to pricing, taking them into account can help ensure you find someone who can deliver the quality you need. Below are some of the essential considerations to bear in mind:

Experience

An experienced custom metal fabricator has the expertise and knowledge necessary to understand the unique challenges of your project. They can provide valuable insights and guidance throughout the process and have likely encountered similar issues. Moreover, they have a proven track record of completing similar jobs. This can provide reassurance that they can handle your project with the same proficiency level.

Assessing a company’s experience requires checking the duration of operations, the range of their projects, and the industries they have served. Requesting references and samples of their past jobs is also beneficial to gauge their skills and proficiency.

Quality Control and Processes

Quality control ensures that the final output meets the required standards, while processes refer to the methods used to manufacture the product. These factors can affect the overall product quality, so choosing a partner that places a high value on these aspects is essential.

A good metal fabrication company has established quality control processes that ensure consistency and quality at every production stage. They have a well-defined quality control system with rigorous testing and inspection procedures. They also follow strict guidelines to ensure the final product meets the required specifications.

Equipment and Technology

Partnering with someone who invests in the latest technology and equipment is essential. This ensures that the company can deliver high-quality products efficiently. They must also have a range of advanced machinery and tools to handle various fabrication processes. In addition, they must have a team of skilled personnel trained to operate the equipment correctly.

Examples of the latest equipment and technologies a company must have included the following:

- 3D printing technology

- Automated press brakes

- CNC machines

- Inspection and testing equipment

- Laser cutting equipment

- Powder coating and painting equipment

- Robotic welding technology

Pricing

It is important to find a metal fabrication company that offers competitive pricing to ensure the quality of services. A potential partner’s pricing evaluation should consider project complexity, materials, and overhead costs. Additionally, an ideal company should have a transparent pricing structure that lists all costs, such as labor, materials, and additional charges.

Sourcing Capabilities

Sourcing capabilities refer to a company’s ability to procure the necessary materials and components for a project. Evaluating someone’s sourcing capabilities means considering their relationships with suppliers and ability to obtain high-quality materials at competitive prices.

Partner With PDF for Quality-Driven Metal Fabrication Solutions

At PDF, we provide high-quality parts and services tailored to our customers’ needs! We specialize in design, fabrication, and manufacturing, and our custom equipment is built to meet the unique requirements of each project.

We have a skilled workforce that can support our customers in many areas, including maintenance, training, robotics, electrical system integration, and electromechanical engineering. Moreover, our fabrication department boasts over 30,000 sq. ft. of fabricating space and 10,000 sq. ft. of indoor storage. This ensures ample room to complete projects efficiently and effectively.

Contact us to learn more about our services, or request a quote today!